Our Strengths:

TRIJAMA has nearly 3 decades of experience in Industrial Air Filters and has continuously strived to improve upon quality standards to enhance product quality and customer satisfaction.

TRIJAMA is located in one of the most technologically developed cities in India i.e. Bangalore. It is a technology and engineering hub with an excellent pool of highly skilled engineering resources and high quality manufacturing set ups. TRIJAMA makes use of these skills while developing new products as well as finding solutions to customers problems. TRIJAMA has modern manufacturing facility with in-house complete metal fabrication facility with CNC shearing and CNC bending machines. It has state of art in-house testing facilities where the filters are tested ensuring reliability in quality. Due to all these, TRIJAMA is a preferred supplier with many large automotive companies who have been giving repeated orders for last 2 decades.

Quality Policy

Trijama Filterall (India) Private Limited is committed to providing products that satisfy our customers needs for quality and delivery through:

Manufacture & supply of quality products with a strong emphasis on customer satisfaction.

Manufacture & supply of quality products with a strong emphasis on customer satisfaction. Commitment to meeting customer requirements through stringent quality checks.

Commitment to meeting customer requirements through stringent quality checks. Continual improvement of products, processes and the effectiveness of quality management system through establishment and achievement of quality objectives

Continual improvement of products, processes and the effectiveness of quality management system through establishment and achievement of quality objectives Building total quality concepts in all activities by creating a strong awareness among all employees through involvement, training, motivation and commitment.

Building total quality concepts in all activities by creating a strong awareness among all employees through involvement, training, motivation and commitment.

- Modern manufacturing facility designed for the filtration products which includes Media cutting and slitting machines, media Pleating Machines, Thermal Welding machines, High speed Imported sewing machines, HEPA paper pleating and Aluminium foil Corrugation Machines etc.

- In-house complete metal fabrication facility with CNC Shearing, CNC Bending machines Mig welding, SS and Aluminium tig welding Machine etc.

- Clean room for manufacturing Higher efficiency Filters.

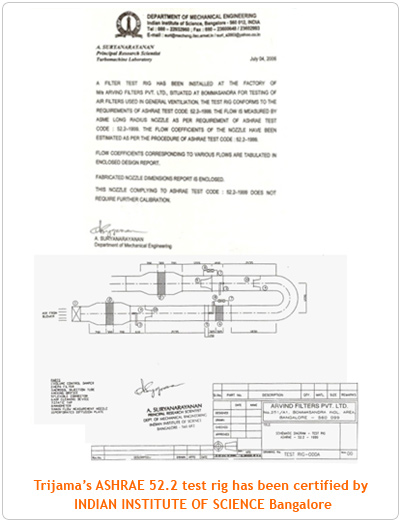

- Testing Rig as per ASHRAE std 52.1.1992 for testing pre ( Primary ) and fine ( secondary) filters and Pocket filters.

- Imported automatic dust feeder for feeding test dust for testing dust weight arrestance of the filters.

- Opacity meter for testing Dust Spot efficiency as per ASHRAE 52.1 Standard.

- High temperature Oven for testing temperature stability of the oven filters.

- Testing Rig as per ASHRAE std 52.2.1999 for testing HEPA filters as per MERV 17 TO 19

- Testing Equipments for testing filter fabrics such as Tensile testing, Bursting strength and Air permeability.

- Testing instruments such as Lazer particle counter, Photo meter, Thermal DOP Generator and Anemo meter ( Velocity meter ).

Parameters tested at trijama

Flow v/s Pressure Drop

Flow v/s Pressure Drop Dust Spot Efficiency

Dust Spot Efficiency Particle Size Efficiency

Particle Size Efficiency Core Tightness Testing

Core Tightness Testing Air Permeability Testing

Air Permeability Testing Water Repellancy Testing

Water Repellancy Testing Bursting Strength

Bursting Strength

Dust Arrestance

Dust Arrestance DOP Efficiecny

DOP Efficiecny Dust Holding Capacity

Dust Holding Capacity Vibration Testing

Vibration Testing Tensile Testing

Tensile Testing Temperature Stability

Temperature Stability